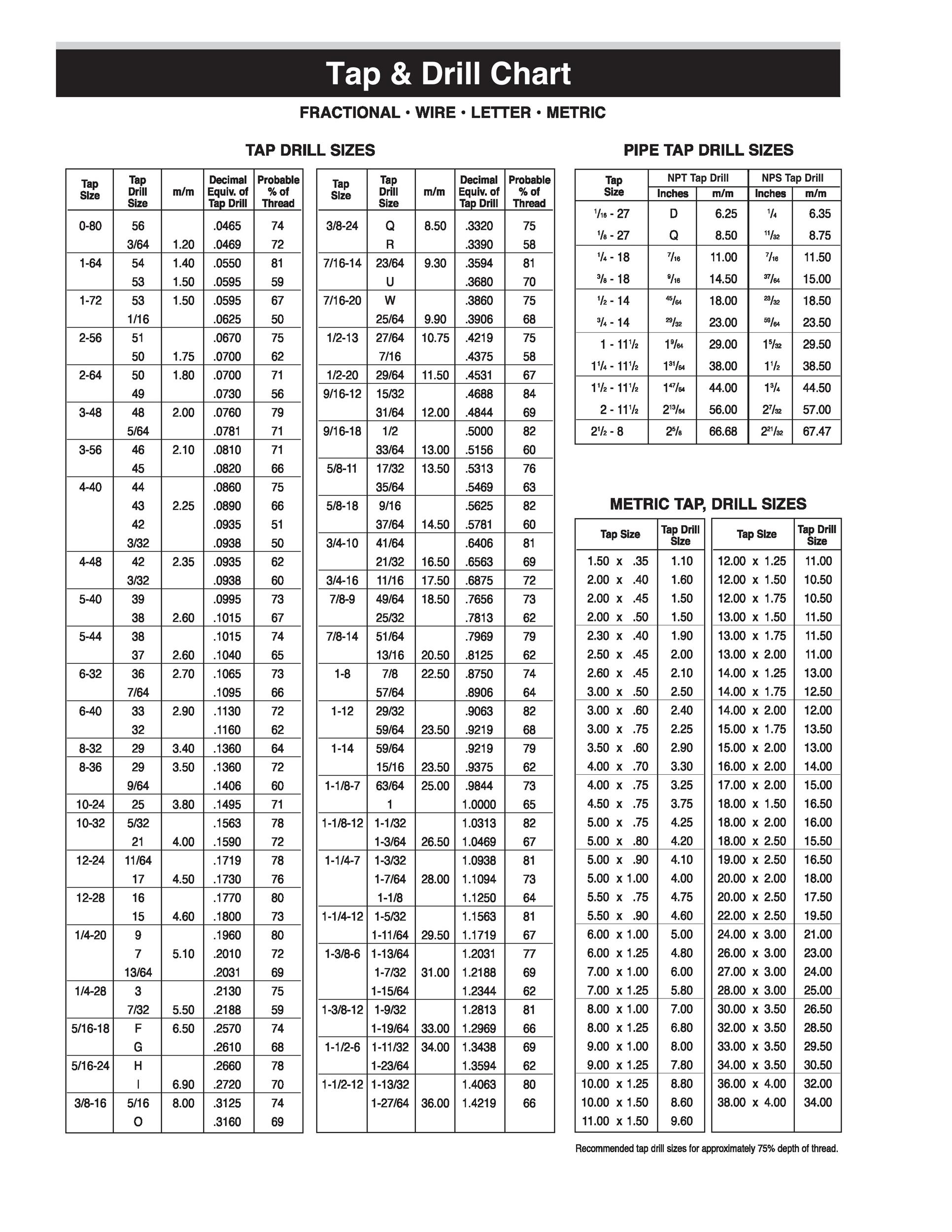

This ensures the larger bits will drill in exactly the right place and won’t walk across the part. This gives the larger bits a center to align to, since most drill bits aren’t perfectly centered when mounted in a drill chuck. It prevents overheating, helps clean out the chips created by the bits, assists the cutting action, and prevents the bits from squealing.Ĭreating a drilled and tapped hole first requires using a center drill. Oil is a necessity while drilling and tapping. Be wary of tap alignment when doing it manually, as the human eye isn’t as accurate as a perfectly 90 degree tap guide. When tapping on a machine such as the Mill or Lathe, the tap is automatically centered and straight. The tap guides, located with the taps, are crucial to creating a straight and usable tap. Information required to select the drill bit includes thread count, diameter, thread pitch, and coarse/fine threads. Tapping is the action that creates a thread into the side of the hole.Ī variety of taps are available to match almost any screw type available, including metric and standard measurements.

Drilling refers to creating a smooth hole in a material with a drill and motor.

What is the difference between drilling and tapping?ĭrilling and tapping are two different actions.

Drill sizes for thread forming taps how to#

Drill and Tap Reference for CNC Machined Partsĭo you have a question about tapped holes on your part? You’re not alone, luckily this guide should answer all of the questions you have about how to add tapped holes to your part.

0 kommentar(er)

0 kommentar(er)